Fuselage Damage Repair

by

Brian Case

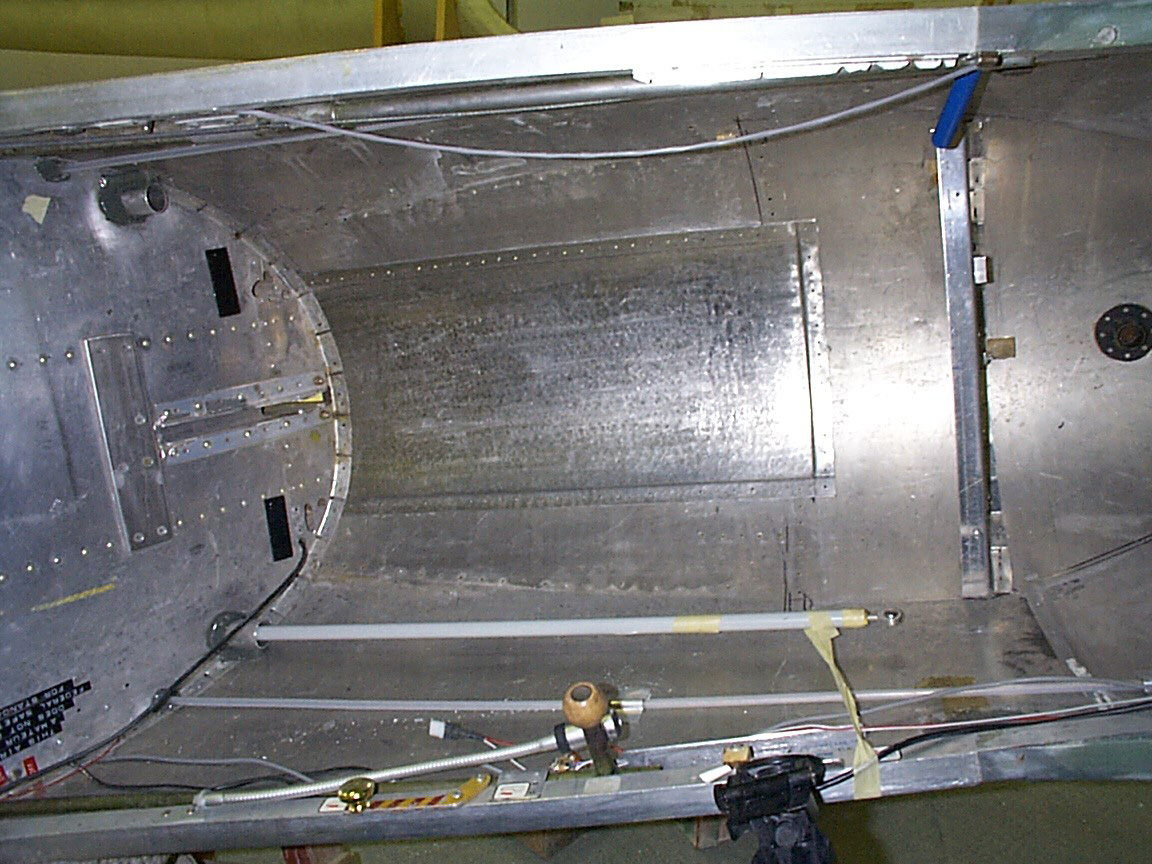

While preparing to install a new center stick system in my HP-16T I decided to repair the damage that resulted from a gear-up landing. The builder had made a simple cosmetic fix by filling and smoothing the damage area with micro balloon.

I drilled out the bulkhead rivets and cut out the damaged portion of the fuselage.

Fabricating the new skin was not that hard but did require some specialized tools and expertise. Fortunately I had an excellent A&P assisting me.

I took the flat oversized piece of aluminum to a heating and cooling sheet-metal shop and had them roll the initial lateral curve of the fuselage skin. I then took it to my A&P. He helped me put the fore and aft curve into it with a planishing hammer.

I then cut it about 1" oversize all the way around. I used a bead roller to put an offset into the edge of the aluminum. (I made custom rollers on the lathe; however, they look similar to the ones shown on the link. The Harbor Freight product may be have adequate rollers for the job.) The offset edge ended up very close to matching the patch to the skin of the fuselage.

Note: I only needed offsets on 3 sides since the back edge was the edge of the gear well. I riveted the new piece into place and filled the small gaps with filler to make the bottom to the fuselage smooth.